ROV Motor

Product introduction

1. Product features

Main features of joint ROV motor:

1. 1. High integration: less overall structural parts, integrating power, transmission and braking

1. 2. High precision control: high speed response, precise positioning, anti-interference;

1. 3. No brush: stable operation, low operation noise, high efficiency and energy saving, long service life;

1. 4. Each wheel has a separate ROV motor drive, which can realize four-wheel drive.

2. Application scenarios

The ROV motor can provide power for various machines. For example, ship blade, Mecanum wheel, crawler, etc., meet the needs of different industries such as industry, scientific research, commerce, medical treatment, etc., with wide application, stable quality and large shipment.

3. Parameter table

Serial numbe | Model | ROV motor |

1 | mm external diameter | 115 |

2 | mm length | 49 |

3 | Nm Rated pitch | 2.5 |

4 | rpm Rated speed | 1050 |

5 | % efficiency | 89 |

6 | W motor power | 280 |

7 | A Rated current | 7.9 |

8 | VDC Rated voltage | 36 |

The above parameters are for reference only. Our product technology is constantly updated and upgraded. At the same time, we also accept the customization and development of customers.

4. Product details

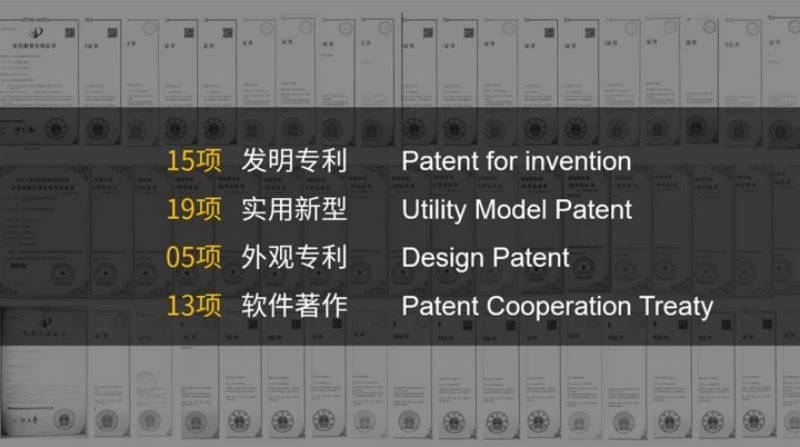

5. Factory and qualification

6. Instructions and precautions

Precautions

1. Check whether the power supply voltage is appropriate before using the new machine (over-voltage may cause damage to the drive module);

2. Do not connect the + / - polarity of DC input wrongly, and check whether the ROV motor model or current setting value on the drive controller is appropriate (not too large at the beginning);

3. Check whether the control signal line is firmly connected, and it is better to do so on the industrial site Consider the shielding problem (such as using twisted pair);

4. Do not connect all the wires to be connected at the beginning, only connect them to the most basic system, and then connect them gradually after the operation is good. Be sure to make sure the grounding method is clear or use floating air instead of connecting. Within half an hour after the start of operation, closely observe the state of the ROV motor, such as whether the movement is normal, sound and temperature rise, and immediately stop the machine for adjustment if any problem is found.

5. Regularly check the servo ROV motor gear and change the oil in time in case of wear and aging. Use less mineral lubricating oil for servo ROV motor lubrication. It is better to use ceramic lubricating oil to avoid deterioration and easy fracture of plastic gear.

6. Regularly check the vibration proof washer of the servo ROV motor. The aging and falling of the vibration proof washer will cause the vibration instrument failure of the servo ROV motor. Do not over lock the washer when installing the servo ROV motor, which will cause the deformation of the vibration proof washer.

7. No waterproof and dustproof ROV motor, please avoid water or dust running into the machine.

8. Do not change the power supply voltage at will, for example, 4.8V for receiver, 6.0V for improving the performance of servo ROV motor to avoid excessive load of servo ROV motor and determine the torque according to the nature of work and the length of swing arm.

Instructions for regular maintenance

1. The interior of the ROV motor shall be inspected regularly and carefully every month, and the dust shall be blown away with a hand-held air box.

2. Check the insulation resistance value every month. If it is found that the insulation resistance value drops, clean up the pollutants on the coil before continuing to use.

3. When the thermal protection and short circuit protection of the ROV motor act continuously, the source of the fault shall be identified, and the fault can be used only after it is eliminated.

4. Clean the air duct blocked by dust and the polluted stator winding every month, which will reduce the heat dissipation, make the ROV motor overheat and reduce the work safety.

5. Retighten the interface screws inside the hub ROV motor or replace the screws quarterly.

Hot Tags: ROV motor, China, manufacturers, suppliers, wholesale, custom, high quality, Robot Joint Actuator, Service Robots Use Flat Motor, Differential Wheel HUB Motor, Brushless DC Motor, Brushless Permanent Magnet Motor, Robotic Motor

Send Inquiry