Rotary Incremental Encoder

1. Main features

1. 1. Quick response

Adapting to change load conditions immediately

High performance fast function ring

Real time performance feedback

1. 2. Stable and compatible

DSP processing task is more reliable and stable

1. 3. High precision control

The resolution of mutual inductance rotary incremental encoder is up to 8768

2. Application scenario

It can be used in CNC machine tools, automatic assembly machines, automatic production lines, textile machinery, automatic production lines, textile, pharmaceutical and other fields to provide high-precision speed or position control for machinery. To meet the needs of different industries such as industry, scientific research, commerce, medical treatment, etc. Widely used, stable quality, large quantity of goods.

3. Parameter Table

The above parameters are for reference only. Our product technology is constantly updated and upgraded. At the same time, we also accept the customization and development of customers.

4. Product details

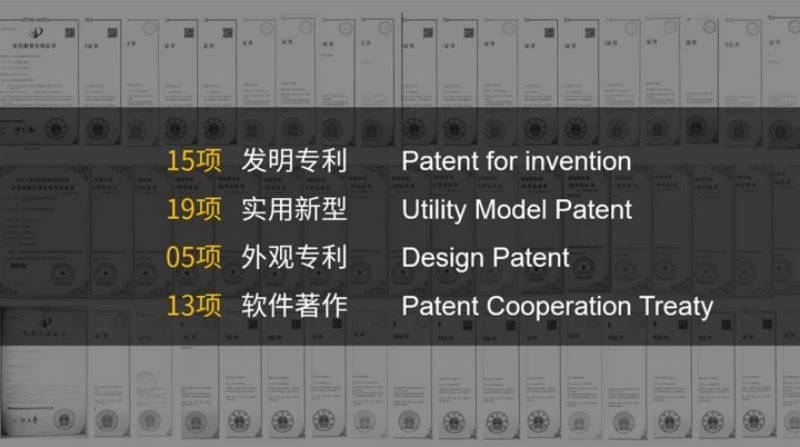

5. Factory and qualification

6. Instructions and precautions

Precautions

6. 1. Do not apply direct impact to the shaft during installation.

Flexible connector shall be used for the connection between encoder shaft and machine. When installing the connector on the shaft, do not press it hard. Even if the connector is used, due to poor installation, it is possible to add more load to the shaft than the allowable load, or cause core pulling phenomenon. Therefore, special attention should be paid.

6. 2. Bearing life is related to service conditions, especially affected by bearing load. If the bearing load is smaller than the specified load, the bearing life can be greatly extended.

Do not disassemble the rotary encoder, which will damage the oil and drip proof performance. Anti dripping products should not be immersed in water and oil for a long time. When there is water and oil on the surface, they should be wiped clean.

6. 3. The vibration added to the rotary encoder is often the cause of the false pulse. Therefore, attention should be paid to the setting place and installation place. The more pulses per revolution, the narrower the slot spacing of the rotating slot disk, and the more susceptible to vibration. When rotating or stopping at low speed, the vibration added to the shaft or body makes the rotating groove disc shake, which may cause false pulse.

6. 4. Wrong wiring may damage the internal circuit, so pay attention to:

Wiring shall be carried out in the off state of the power supply. When the power supply is connected, if the output line contacts the power supply, sometimes the output circuit will be damaged.

If the wiring is wrong, sometimes the internal circuit will be damaged, so pay full attention to the polarity of the power supply when wiring.

If the wiring is parallel with the high-voltage line and power line, it may be damaged due to induction sometimes, so separate the wiring.

7. FAQ

What kind of situation we need to choose rotary incremental encoder?

A: 1. The data safety and reliability of power cut moving, and inertia sliding are very important for some safety equipment, large equipment and lifting engineering equipment that need height and length measurement. In order to ensure the stability and reliability of encoder data, full stroke absolute value encoder must be selected. If the encoder data error occurs in this kind of application, the loss may be far more than the encoder cost itself. For example, the height and length measurement of sluice, construction machinery, crane, elevator, gantry crane, etc.

2. For the problem of signal anti-interference, sometimes the labor cost is far greater than the cost of an encoder. The incremental signal is vulnerable to various interferences, and the data acquisition is unstable. For various unpredictable interferences on site, a lot of effort will be spent on troubleshooting, and try to avoid interferences. In this case, the absolute value encoder should be replaced. For example, for all kinds of automation engineering projects, when the on-site inverter, switching power supply, and grounding conditions are unknown, there is no way to judge the interference situation, and selecting absolute value encoder can ensure to deal with various working conditions.

3. The follow-up equipment saves resources. The incremental encoder needs high-speed counting, which consumes CPU resources

Www.xiaocaocaofanwen.com: instructions for absolute value encoder)

For more high-speed counter ports, the absolute value encoder is selected for serial transmission

Hot Tags: rotary incremental encoder, China, manufacturers, suppliers, wholesale, custom, high quality, Photoelectric Sensor Module, Load Cell Module, Fingerprint Sensor, Temp Sensor, Torque Sensor, Pressure Sensor

Send Inquiry