Heavy Duty Mecanum Wheel

1. Introduction of heavy Mecanum wheel

Based on the traditional heavy Mecanum wheel, RoboCT heavy Mecanum wheel module integrates gear motor, encoder and special shock absorber, which has a higher degree of compactness and flexibility. It is the new generation of heavy Mecanum wheel. Based on the characteristic of heavy Mecanum wheel, Omni-Directional motion equipment can achieve different types of movement,including forward, sideways, rotation and combination movement. Besides, it has significant adaptability and widely application area in the stage of limitation of transfer space and narrow working channel.

Main feature of heavy Mecanum wheel:

1. Flexible movement: Omnidirectional movement technology can make heavy Mecanum wheel move in any direction, zero turning rotation.

2. Compact structure: Integrated hub motor, encoder, high space utilization, easy to integrate design.

3. Stronger load: compare with other same size wheel, heavy Mecanum wheel can take more weight.

4. Longer life: only need to change rollers to instead of changing wheels.

Main feature of motor:

1. Simple structure:Less components, easy to install and design.

2. Low speed: Stable, lower noise.

3. High precision: High speed response, precise positioning, anti-interference.

4. Lower price: Proprietary structural design, special manufacturing process.

2. Application scenario

Heavy Mecanum wheel module can be applied to mobile robots, warehousing robots, logistics robots, AGV, AMR, intelligent parking equipment, general robots etc., to satisfy the needs of different companies such as industry, scientific research, commerce, medical equipment etc. A wide range of applications, stable quality and large shipment.

3. Parameter table

| NO. | Model | CTM1000-10R |

| 1 | Payload (A set of four) | 1000kg |

| 2 | Dimension | 106.9mm * diameter φ 240mm |

| 3 | Weight | 25kg/wheel |

| 4 | Gear ratio | 37.1 |

| 5 | Rated torque | 74NM |

| 6 | Best efficiency point torque | 74NM |

| 7 | Rated output velocity | 56rpm |

| 8 | Input voltage | 24-48V |

| 9 | Motor power | 220-440W |

| 10 | Environmental suitability | Indoor |

| 11 | IP level | IP44 |

| 12 | Encoder form | Magnetic |

| 13 | Resolution | 4096 Wire |

The above parameters are for reference only, please contact us for up-to-date specifications. At the same time, we also accept customization and new design.

4. Product details

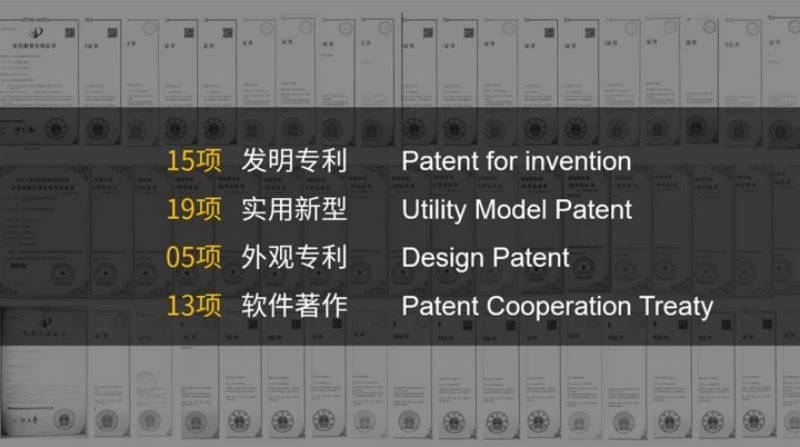

5. Factory and Qualification

6. Instructions and Precautions

Operation mode

(1) When power on, please make sure that the motor axis remains stationary and will not rotate due to mechanism inertia or other factors

(2) When the motor is running, do not touch any rotating motor parts, otherwise it may cause personal injury

(3) In order to avoid accidents, please separate the coupling and belt of mechanical equipment to make it in a separate state, and then carry out the first test run.

(4) After the servo motor is connected with the mechanical equipment, if the operation error occurs, it will not only damage the mechanical equipment, but also cause personal injury sometimes.

(5) It is strongly recommended that: please test the normal operation of the servo motor without load, and then connect the load to avoid unnecessary danger.

(6) During operation, please do not touch the heat sink of servo driver, otherwise it may be scalded due to high temperature

(7) Do not touch the inside of servo driver and servo motor, otherwise electric shock may be caused.

(8) When the power is started, do not remove the drive panel, otherwise it may cause electric shock.

(9) Do not touch the terminals within 10 minutes after the power is turned off. Residual voltage may cause electric shock.

(10) Do not disassemble the servo motor, otherwise the motor may be damaged or accidents may occur during use.

(11) Do not change the wiring with the power on, otherwise electric shock or personal injury may be caused.

(12) Only qualified motor professionals can install, wire and repair the servo driver and servo motor

Instructions for regular maintenance

- Wipe the surface of perpendicularity adjusting part to avoid affecting the accuracy.

- Adjust the verticality adjusting parts regularly to ensure that the heavy Mecanum wheel is in a vertical state.

- Before each start-up, the sundries within the operation range of the machine must be removed with an air gun, the power supply must be connected, the machine must be started, and the operation condition of the machine must be checked.

- Check whether the fastening screws are loose.

- If the machine is not used for a long time, please wipe it clean and put it in a dry and ventilated environment. Do not store it in a place with high temperature and humidity.

--Every season, the motor bearing needs to be replaced with oil to ensure that the motor runs without resistance.

- Every season, the oil of shock absorption bearing needs to be changed to ensure the smooth running of heavy Mecanum wheel.

FAQ

Q: How can I get a quote?

A: Contact the sales, it’s necessary to know your company and project info before giving a quote, RoboCT have standard questions for you to reply. You can also email us. The mail is wuyizhi@roboCT.com

Q: What’s your company advantages?

A: High cost-effective goods, high-level technology products and perfect after-sales service.

Hot Tags: heavy duty mecanum wheel, China, manufacturers, suppliers, wholesale, custom, high quality, Integrated Mecanum Wheel Module, Heavy Duty Mecanum Wheel, Industrial Mecanum Wheel, Mecanum Wheel, Mecanum Omnidirectional Wheel, Mobile Robot Components

Send Inquiry